Blog

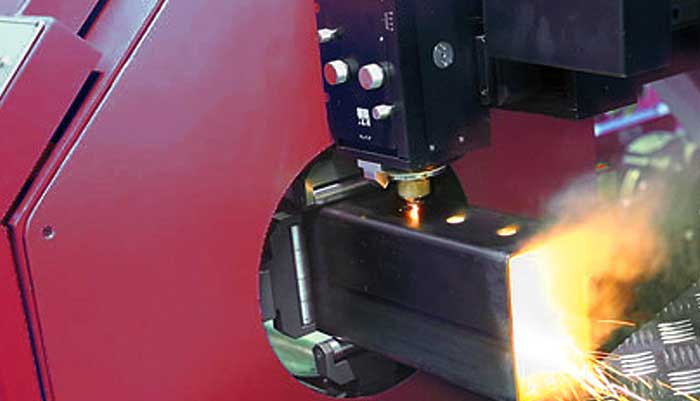

Fiber lasers have high cutting speeds for thin material. These fiber lasers require minimal maintenance and have low power consumption. These laser cutting technologies have special properties, which allow them to be used in steel, stainless, aluminum, and other non-ferrous materials, like copper, brass, and bronze.

Due to the power required to make a CO2 laser it is much less efficient than a fiber laser and has a lower wall plug efficiency. The large chillers needed to create CO2 lasers require more power overall. The fiber laser resonator has a wall plug efficiency of over 40 percent so you not only use less power but also take up less of your high-demand floor space.